Quality Control : Components visual inspection at G 4 SOURCING

November 20, 2023

Incoming inspection is a very important step in our business. After consulting our various suppliers, we have to make sure that the components we receive correspond to the reference we have ordered for our customer. Packing and packaging must correspond to the specific features of the reference received. To simplify the explanation, we’ll take a few examples to illustrate what we expect from a supplier and what we don’t want.

Quality control

ESD (Electrostatic discharge) compliance

Static electricity can damage or even render unusable integrated circuits. To avoid any risk of product deterioration, we use anti-static equipment (ESD gloves, ESD mats, etc.). All sensitive components are placed in ESD bags to protect them from potential static discharges. ESD bags are generally pink or transparent gray, or shielded.

Moisture Sensitive Level (MSL) compliance

Some components are sensitive to humidity. In fact, to prevent lead oxidation (in the case of LEDs) or delamination (in the case of BGAs) during the melting process, it is important to keep these components in hermetically sealed ESD packaging with a desiccant bag to preserve their quality and performance.

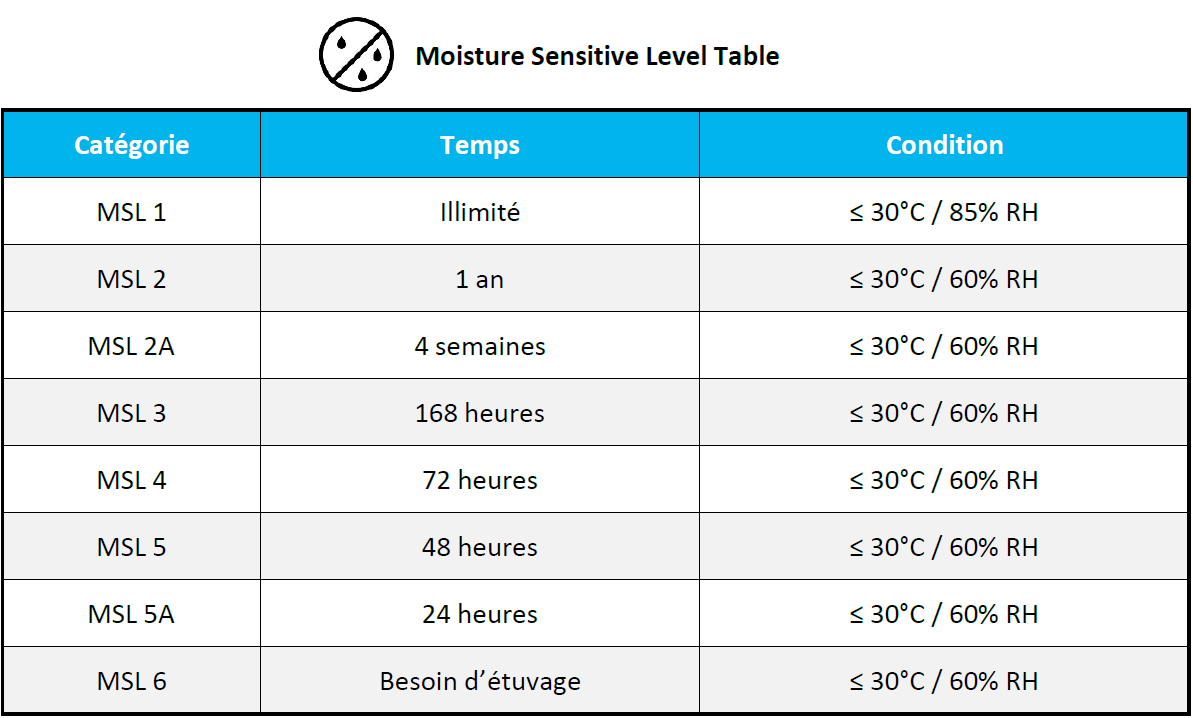

There are several categories of component sensitivity, ranging from MSL 1 to MSL 6. More commonly, you’ll find components between levels 1 and 3 (or even 4, but this is a little rarer). Categories 5 and 6 are highly sensitive components, often reserved for dedicated use in aerospace equipment.

Below you’ll find a table listing these categories and the length of time they can be left in the open air without needing to be steamed.

Note: We recommend steaming components with an MSL level of 2 or above, to reduce the risk of failure. Proofing is even more necessary when products are of older code dates.

Quality control: Components visual inspection

We inspect all the parts we receive. Twisted lugs, oxidation, wrong reference, wrong packaging, direction of marking, correspondence with the product data sheet… If any doubt persists, we carry out further laboratory analysis (acetone solution, X-rays…), to guarantee that the parts are genuine.

Indeed, although very rare today, counterfeits still exist. The presence of the manufacturer’s original label is always reassuring, and when we can, we provide a copy of it when we deliver your components.

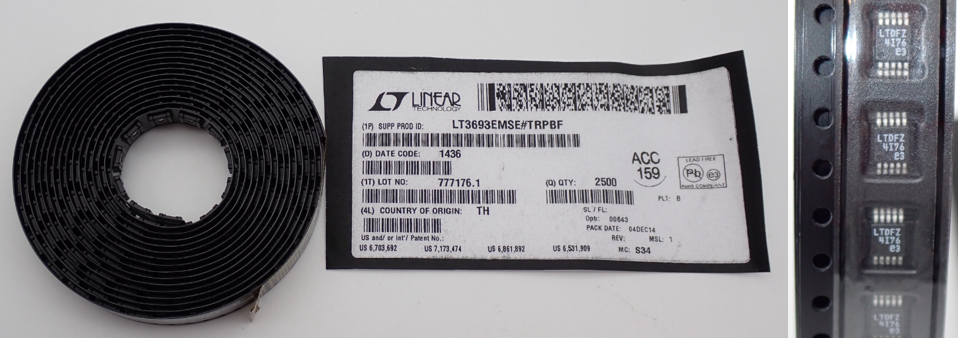

Quality control: Example of a compliant component

This is a perfect example.

Unopened original packaging with:

- Original label including lot number

- Quantity

- Date code

- Country of origin

Parts received with ESD packaging and distributor label.

- ESD packaging

- Manufacturer’s label (or photocopy)

- Belt intact and unaltered

- Component marking corresponding to technical data sheet

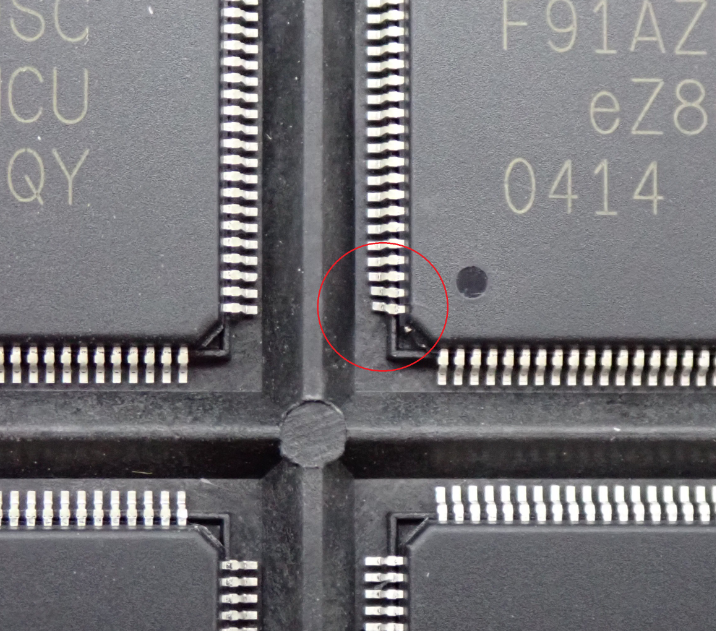

Quality control: Examples of non-conforming components

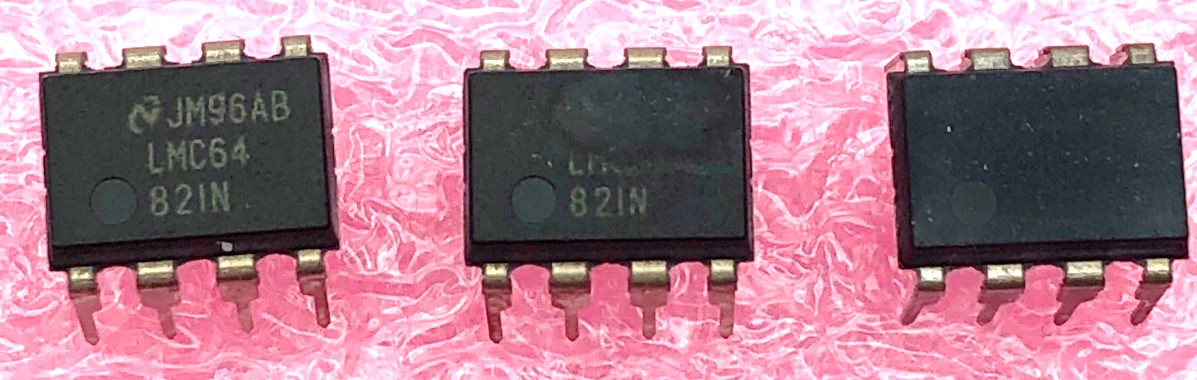

The components are MSL 3.

Although the components are in ESD packaging, the packaging must be opaque/metallized (ESD shield bag).

There is no desiccant in the packaging.

We also note that the trays have not been strapped. There is a risk of mishandling and therefore of the legs being bent.

After opening the packaging, we observe some folds on some of the legs of several components.

Photos will be sent to the supplier to support our RMA (Return of Material Authorization) request.

In this photo, we proceeded an acetone test.

Marking on genuine parts should be permanent. However, it fades. The components are therefore counterfeit.

RMA requested from supplier

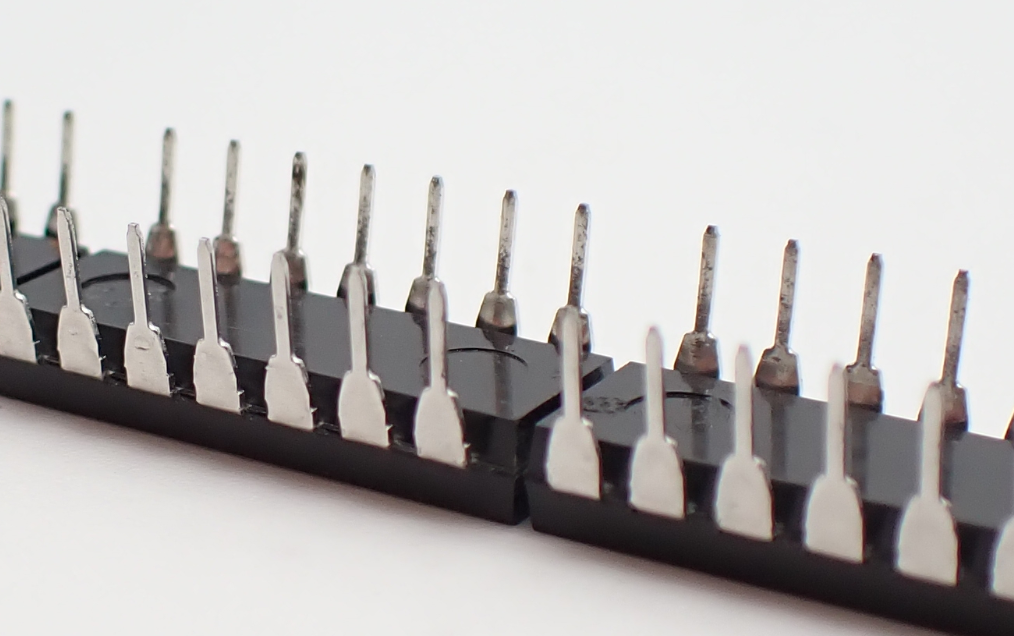

Presence of oxidation on inner part of DIP component.

RMA requested from supplier.

Folding at different levels of the belt. The belt or the components inside may be damaged.

The belt has also been wound in the wrong direction, making the transparent film bonded to the belt even more fragile.

RMA requested from supplier.

Quality control: Examples of acceptable components

Ideally, a lot number is preferable to ensure traceability.

For legal reasons, some labels arrive erased or crossed-out. For some customers, this may pose a problem, but the parts are functional and authentic.

So they won’t be a problem for assembly. What’s more, the lot number can often be found on the component marking.

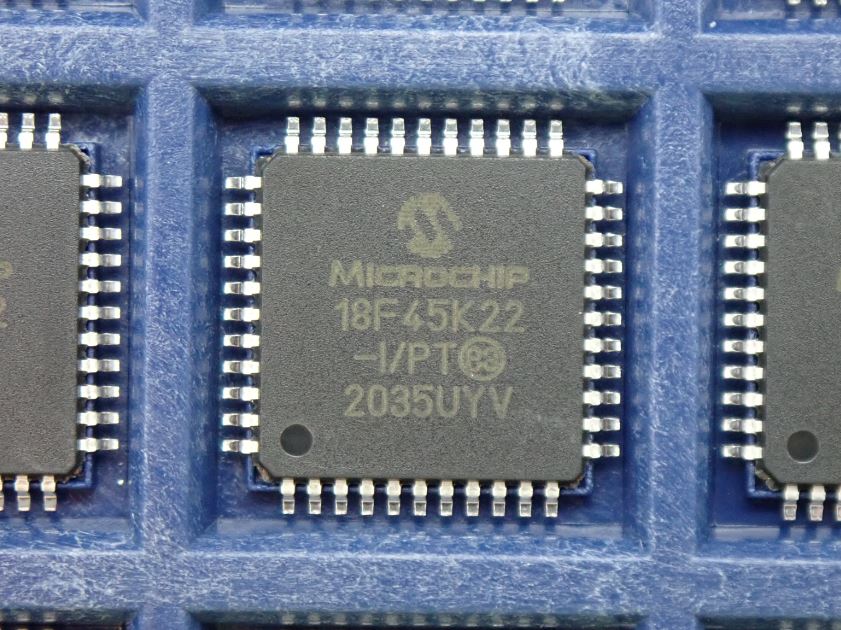

Despite the absence of the original part number label, the part marking gives us all the information we need to reference it in our system.

Manufacturer: Microchip Microchip Microchip

Manufacturer reference : PIC18F45K22-I/PT

Date code: 2020/35

COO : Thailand (visible on back of component)

The legs of the component show no signs of oxidation or deformation. According to the data sheet, this component is not MSL 3 as it comes from the Microchip factory in Thailand. The components are acceptable.

News & Blog

Keep up with everything G 4 SOURCING news!

J2 Sourcing Acquires 100% of G4 Sourcing in France to strengthen market presence

Press ReleaseJ2 Sourcing Acquires 100% of G4 Sourcing in France to Strengthen Market PresenceMalmö, Sweden -...

Our management of exports and ECCNs

ECCN classification: We update our procedures to comply with international regulationsDecember 08, 2023The U.S....

G 4 SOURCING official sponsor of motorcycle rider Randy De Puniet

G 4 SOURCING official sponsor of motorcycle rider Randy De Puniet for 2023 ECW 202310 Janvier 2023We are delighted to...